In the modern industrial landscape, the finish of a product is no longer just about aesthetics or basic corrosion resistance. As global industries pivot toward a circular economy and stricter environmental regulations, the “how” and “why” behind surface coatings have come under intense scrutiny.

For architects, engineers, and manufacturers, the choice of coating is now a strategic decision that impacts a project’s carbon footprint, its longevity, and its safety profile. At Superior Coaters, we believe that understanding the chemistry and environmental benefits of powder coating is essential for making informed, sustainable choices.

This article dives deep into the molecular science of powder coating and explores why it stands as the gold standard for eco-friendly industrial finishing.

The Chemistry of Resilience: How Powder Works

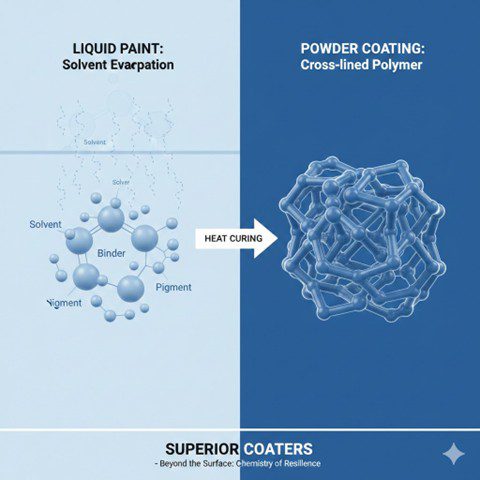

To understand the sustainability of powder coating, one must first understand its chemistry. Unlike liquid paint, which relies on a solvent (a chemical carrier) to keep the binder and pigment in a liquid state, powder coating is a dry finishing process. It is comprised of thermoplastic or thermoset polymers, pigments, and additives that are ground into a fine flour-like consistency.

The Thermoset Transformation

The most common industrial powder coatings are thermoset. During the curing process in our ovens, the powder undergoes a chemical cross-linking reaction. When exposed to heat, these particles melt, flow, and chemically bond to form a higher molecular weight polymer network.

This isn’t just a physical change; it is a molecular one. Once cured, a thermoset coating cannot be remelted back into its original form. This “one-way” chemical bond provides the coating with its legendary resistance to heat, chemicals, and mechanical impact.

Polyester vs. Epoxy: Choosing the Right Molecule

The chemistry is tailored to the environment. For example:

- Polyester Powders: These are the workhorses of architectural finishing. Their molecular structure is highly resistant to UV degradation, making them ideal for the harsh Australian sun.

- Epoxy Powders: While extremely tough and chemically resistant, epoxies tend to “chalk” when exposed to sunlight. Therefore, they are reserved for functional, indoor, or underground applications where durability is the only metric that matters.

By selecting the specific polymer chemistry for the application, we ensure the product lasts for decades, preventing the “throwaway culture” of frequent recoating.

The Environmental Edge: A Zero-VOC Solution

The most significant environmental advantage of powder coating lies in what it doesn’t contain.

Eliminating VOCs

Traditional liquid paints are often loaded with Volatile Organic Compounds (VOCs). These chemicals are necessary to keep the paint liquid, but they evaporate as the paint dries, contributing to “smog,” ground-level ozone, and respiratory issues for workers.

Powder coating contains zero or near-zero VOCs. Because there is no solvent to evaporate, the air quality inside and outside the coating facility remains significantly cleaner. For projects aiming for Green Star certification or LEED points in Australia, the absence of VOCs is a critical requirement.

The Absence of Heavy Metals

Historically, industrial coatings relied on chrome-based pre-treatments and lead-based pigments for colour and corrosion resistance. Modern powder coating chemistry has evolved. At Superior Coaters, we utilize advanced pre-treatment stages that move away from traditional hexavalent chrome, opting for more stable, environmentally responsible conversion coatings that provide superior adhesion without the toxic legacy.

Waste Minimization and the “Over-Spray” Advantage

In liquid spray painting, “over-spray” (the paint that misses the target) is essentially lost. It becomes a hazardous waste product that must be captured in filters and sent to landfills.

Powder coating operates on a principle of resource efficiency:

- The Electrostatic Attraction: The powder is charged with static electricity as it leaves the spray gun, while the part being coated is grounded. This creates an “attraction” that wraps the powder around the part, significantly reducing waste from the outset.

- Reclamation (The Closed Loop): In a controlled powder booth environment, over-sprayed powder can be collected, filtered, and reintroduced into the feed hopper. This means a powder coating line can achieve up to 95–98% material utilization.

- No Hazardous Sludge: Because there are no solvents to mix, there is no “paint sludge” to dispose of. The small amount of waste generated is typically a non-hazardous solid that has a much lower environmental impact than liquid chemical waste.

Energy Efficiency and the Carbon Footprint

Critics of powder coating often point to the energy required to run curing ovens. However, when viewed through the lens of a Life Cycle Assessment (LCA), powder coating often has a lower total carbon footprint than liquid alternatives.

- Reduced Air Handling: Because there are no VOCs to exhaust, powder coating facilities don’t need to move massive volumes of heated air out of the building to keep workers safe. This significantly reduces the energy load on HVAC systems.

- Single-Pass Efficiency: Powder coating achieves a thick, durable finish in a single coat. Liquid systems often require a primer, multiple colour coats, and a clear topcoat—each requiring its own drying or curing time. By reducing the process to a single “heat cycle,” we save time and energy.

Longevity: The Ultimate Form of Sustainability

Perhaps the most overlooked aspect of sustainability is durability. A product that needs to be repainted every five years is inherently less sustainable than one that lasts twenty-five.

The mechanical bond formed during the powder curing process is significantly more resistant to chipping, scratching, and fading than liquid paint. In the context of Australian infrastructure—where salt air and high UV levels act as a constant abrasive—the “over-engineered” nature of powder coating chemistry acts as a shield. By extending the life of the underlying metal (whether it’s aluminium or steel), powder coating preserves the “embodied energy” of the metal itself, preventing premature corrosion and the need for replacement.

The Superior Coaters Verdict

The shift toward sustainable manufacturing isn’t a trend; it’s a fundamental change in how we build the future. The chemistry of powder coating—rooted in solid-state polymers, electrostatic efficiency, and the elimination of toxic solvents—offers a rare “win-win” scenario. It provides a finish that is tougher and more aesthetic than liquid paint, while simultaneously protecting the health of the planet and the people who apply it.

At Superior Coaters, we aren’t just applying a colour; we are applying a scientifically engineered protective layer. By choosing powder coating, you are opting for a process that values resource efficiency, embraces advanced chemistry, and stands the test of time in the most demanding environments.

Whether you are designing architectural facades or industrial machinery, the choice is clear: look beyond the surface, and you’ll find that the most beautiful thing about modern powder coating is its science.

07 3375 6777

07 3375 6777