Premium Metal and Steel Powder Coating Services

At Superior Coaters, we specialise in applying tough, high-quality powder coatings to all types of metal, from small parts to oversized steel structures. Our advanced facility in Brisbane offers reliable, high-performance results every time.

Why Choose Powder Coating for Steel & Metal?

- Durability – Powder coating offers exceptional durability, providing a robust finish that is highly resistant to chipping, scratching, fading, and corrosion. This makes it a superior choice for applications exposed to harsh conditions, often lasting 15-25 years or even longer with proper application and maintenance.

- Eco-Friendly – powder coating contains no volatile organic compounds (VOCs) or hazardous air pollutants (HAPs), and overspray can be collected and reused, significantly reducing waste compared to liquid coatings.

- Custom Finishes – Powder coating offers an extensive range of custom colour options, allowing for precise matching to brand guidelines or unique aesthetic visions. This versatility enables designers and manufacturers to achieve distinctive looks and consistent branding across various products and components. Huge range of colours and textures

- Weather-Resistant – Powder coating provides excellent weather resistance, forming a tough barrier against UV radiation, moisture, and extreme temperatures. This superior protection prevents fading, chalking, and corrosion, making it an ideal choice for outdoor applications requiring long-term aesthetic and functional integrity.

What We Powder Coat

Items:

- Structural Steel Frames

- Gates & Fencing

- Machinery Parts

- Aluminium Panels

- Balustrades

- Custom Fabrication Work

Our Powder Coating Process

Surface Prep – Sandblasting or Chemical Treatment

The foundation of a durable powder coat lies in meticulous surface preparation. Depending on the material and its condition, we employ either sandblasting to remove rust, old paint, and impurities, or a specialized chemical treatment for a thorough clean and optimal adhesion. This critical step ensures that the metal surface is perfectly profiled and free from contaminants, allowing the powder to bond effectively and prevent future issues like bubbling or peeling.

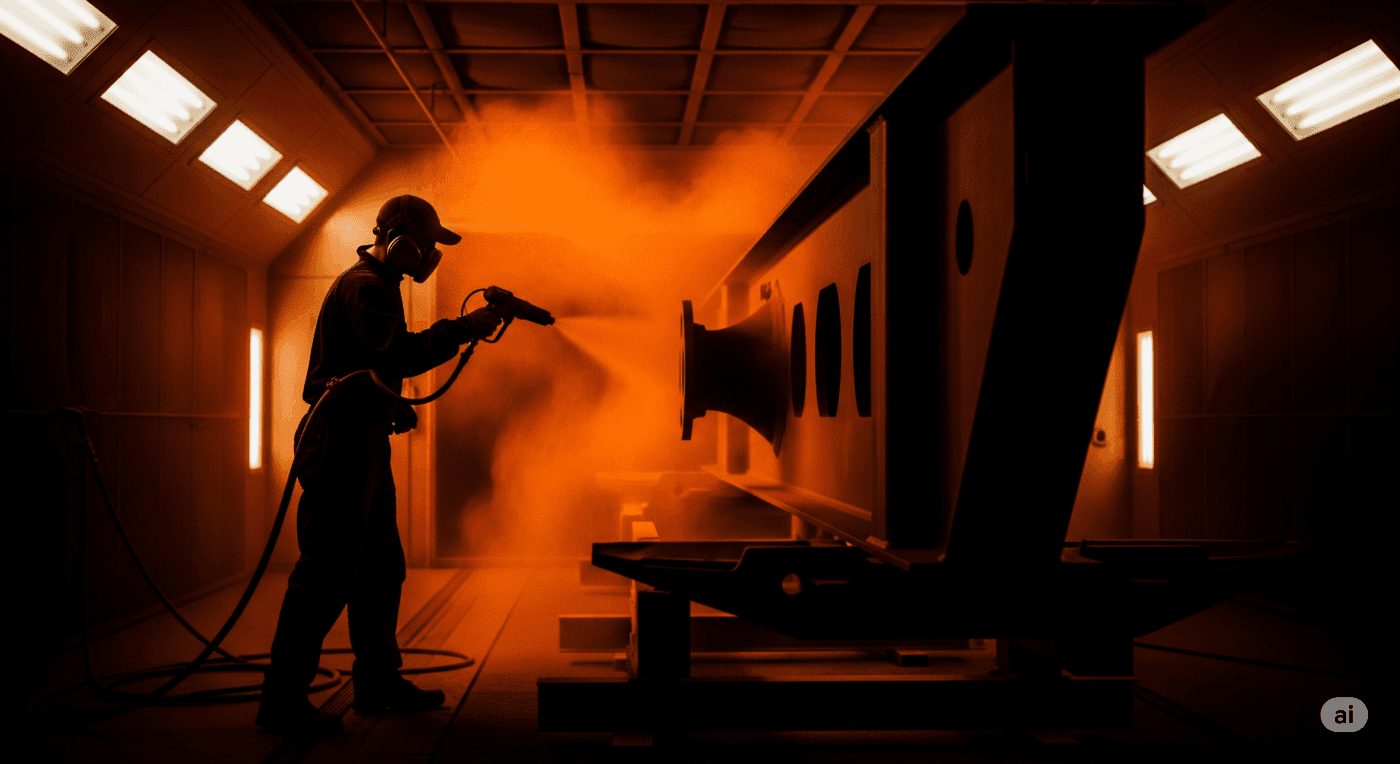

Application – Electrostatic Powder Spray

Once prepped, the item moves to the application stage, where a finely ground powder made of resin, pigments, and additives is applied. We utilize an electrostatic powder spray method, which electrically charges the powder particles. These charged particles are then attracted to the grounded metal surface, ensuring an even, comprehensive, and consistent coating that adheres precisely to every contour of the item.

Curing – High-Temp Baking in Our 14-Metre Oven

Following application, the coated item enters our state-of-the-art 14-meter oven for curing. Here, it undergoes high-temperature baking, typically between 160°C and 200°C. This heat causes the powder particles to melt, flow out, and chemically cross-link, transforming them into a smooth, continuous, and extremely durable protective layer that is bonded to the metal.

Inspection – Quality Checked for Finish & Coverage

The final and crucial step is a comprehensive inspection. Each piece is meticulously quality checked for both its finish and coverage. Our experts examine the item for any imperfections, ensuring a uniform thickness, consistent color, and a flawless surface free from blemishes, guaranteeing that every product meets our stringent standards for aesthetics and longevity.

07 3375 6777

07 3375 6777