In Australia, the choice of a metal coating finish is not merely an aesthetic decision—it is an engineering mandate. The relentless combination of high-intensity ultraviolet (UV) radiation, extreme temperature fluctuations, and corrosive coastal salt environments demands a level of material performance unmatched in many other parts of the world. For architects, engineers, and fabricators of high-value assets—from architectural facades and public infrastructure to commercial equipment—understanding the technical differences between powder coating finishes is the key to ensuring longevity, maintaining visual integrity, and protecting the underlying investment.

A superior powder coating system is a multi-layered defence, but the visible topcoat is the frontline against UV degradation, chalking, and fading. Selecting the right finish requires a strategic balance between desired aesthetic (matte, gloss, texture, colour) and necessary chemical performance.

The UV Stability Hierarchy: Why Chemistry Matters

The single greatest factor determining a powder coating’s long-term performance in the Australian environment is the resin chemistry used in the formulation. When exposed to harsh UV light, the polymer chains in lower-grade powders begin to break down, leading to chalking (a white, powdery residue) and colour fading.

The available chemistries form a hierarchy of UV resistance:

1. Standard Epoxy (Indoor Use Only)

Performance: Excellent chemical and corrosion resistance, high durability. UV Rating: Poor. Application Note: Epoxy powders are suitable only for internal use (e.g., machinery, indoor shelving). They will rapidly chalk and fade when exposed to sunlight, making them unsuitable for any exterior application.

2. Standard Polyester (General Exterior)

Performance: Good durability, strong weather resistance, and cost-effectiveness. UV Rating: Good. Application Note: Standard polyesters are the go-to choice for general outdoor applications like garden furniture, fencing, and non-critical architectural pieces. However, for high-end or infrastructure projects where colour and gloss retention are paramount, a higher-grade option is required.

3. Super Durable Polyester

Performance: Enhanced UV resistance, improved gloss retention, and longer service life compared to standard polyester. UV Rating: Excellent. Application Note: Often mandated for architectural projects, these powders use advanced resin technology to slow down the degradation process significantly. They are a reliable and cost-effective choice for a vast range of demanding external applications in Queensland and Australia-wide.

4. Fluoropolymer (FEVE/PVDF) Coatings

Performance: The gold standard for maximum UV stability, colour retention, and weather resistance. UV Rating: Superior. Application Note: Systems using Fluoropolymer (FEVE) resins, such as those in the Dulux D3000 or Interpon Metaplex Commercial range, are specified for landmark architectural projects, high-rise buildings, and critical infrastructure (e.g., bridge components, major facades). While they carry a higher material cost, their virtually unmatched longevity and colour fastness ensure the lowest total life cycle cost.

Choosing the right powder isn’t an over-specification; it’s a critical preventative measure against the high cost of premature recoating or structural failure.

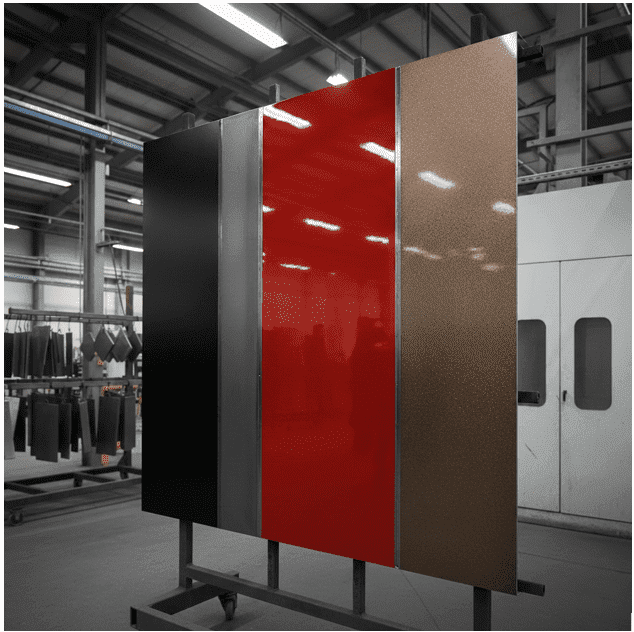

The Aesthetic Spectrum: Gloss, Matte, and Texture

Beyond chemistry, the visual finish itself has technical implications for perceived longevity, cleaning, and light reflection.

1. Gloss Level: Where Perception Meets Performance

The gloss level—ranging from High Gloss (90%+ ) to Matte (30% and below)—measures the degree of specular (mirror-like) reflection from the surface.

- High Gloss (70%+): Offers the deepest colour appearance and is easy to clean. However, any surface imperfection, dust, or—crucially—the onset of chalking will be immediately and visibly apparent.

- Semi-Gloss to Satin (30%–70%): A balance of cleanability and moderate hiding of minor surface imperfections. This is a common choice for commercial assets.

- Matte (30% and Below): A sophisticated architectural look. Matte finishes tend to hide the visual effects of chalking for longer, as they already scatter light. For highly exposed environments, a matte finish in a super durable chemistry can offer the best visual compromise—a premium look backed by exceptional chemistry.

2. Textured Finishes (Rivers, Veins, Ripples)

Textured powders offer a functional benefit by masking substrate imperfections (like weld splatter or surface pitting) and providing superior scratch and scuff resistance.

- Functionality: The physical texture adds a microscopic topography that makes the coating tougher and helps deflect glancing blows. This is ideal for high-traffic or industrial equipment where mechanical damage is a concern.

- Maintenance: While durable, the texture itself can sometimes trap environmental dirt or dust, requiring more careful cleaning than a smooth gloss finish.

Speciality Finishes: Metallic and Anti-Graffiti Considerations

Achieving striking effects like metallic sheens or offering high-level protection requires specific application and formulation techniques.

Metallic and Pearlescent Finishes

A metallic finish achieves its look by incorporating tiny metal flakes (usually aluminium or mica) into the powder. This presents two main technical challenges in application and durability:

- Pigment Orientation: The metal flakes must be perfectly aligned to achieve a uniform sheen. Any variation in application (like an inconsistent electrostatic charge or powder flow) can result in a patchy appearance known as “tiger striping” or mottling. This demands the highest level of applicator skill and state-of-the-art equipment.

- UV Protection (for Bonded Metallics): Some metallic powders are “bonded” (where the metallic pigment is physically bonded to the base powder particle) to improve application consistency. For non-bonded or highly aesthetic metallic effects, a clear powder topcoat may be necessary. This clear coat protects the metallic pigment itself from direct UV exposure and corrosion, enhancing both the effect and the overall durability.

Anti-Graffiti Coatings

In public and community infrastructure projects, anti-graffiti powder coatings offer a crucial layer of long-term protection.

- Mechanism: These coatings are based on highly cross-linked polymer systems that create a non-stick, very low-porosity surface. This prevents spray paint or markers from penetrating the coating’s surface.

- Cleaning: Graffiti can be removed using stronger solvents or high-pressure washing without damaging the underlying coating, allowing for repeated removal over the asset’s lifetime.

The Foundation of Finish: Pre-Treatment is Paramount

Even the most chemically advanced powder coating will fail prematurely if the underlying metal surface is not prepared correctly. Preparation is not a negotiable pre-step; it is the foundation of the finish.

At Superior Coaters, the process is built on a rigorous multi-stage system that goes beyond simple cleaning:

- Abrasive Blasting (Grit Blasting): For highly corrosive environments or heavily scaled steel, abrasive blasting removes rust, mill scale, and old coatings. This creates a profile (anchor pattern) on the metal surface, which is essential for the powder to grip and bond mechanically.

- Four-Stage Chemical Pre-Treatment: This typically involves degreasing, rinsing, and the application of a conversion coating (such as zinc phosphate). This conversion layer chemically bonds to the metal, significantly improving the adhesion of the powder and dramatically boosting the corrosion resistance.

- Primer (Zinc-Rich Epoxy): For coastal or severe industrial environments, a high-performance system requires a zinc-rich epoxy primer beneath the topcoat. Zinc acts as a sacrificial barrier, protecting the steel even if the topcoat is scratched—a process known as cathodic protection.

By starting with meticulous surface preparation and concluding with high-performance topcoat chemistry, applicators like Superior Coaters ensure that the matte black fence or the metallic architectural feature is not just beautiful on installation, but remains robustly protected against the rigours of the Australian environment for decades to come.

For any project facing high UV, salt, or corrosive elements, consulting with an accredited applicator who understands the chemistry and engineering standards is the only way to safeguard your asset and ensure the finish performs exactly as specified.

07 3375 6777

07 3375 6777