In the world of metal fabrication, architecture, and large-scale industrial projects, the final powder coating finish is often the only element visible. It’s what provides colour, texture, and—most critically—protection. Yet, the finished layer of coating is only as strong as the preparation beneath it. At Superior Coaters, with decades of experience handling oversized structures and high-performance industrial assets, we know a fundamental truth: The performance of a powder coating is 10% material and 90% preparation.

For engineers, architects, and project managers specifying high-value components, understanding the science of pre-treatment is paramount. Skipping or simplifying this initial phase is the single greatest risk to asset integrity. It’s the difference between a coating that lasts for decades, enduring harsh Australian conditions, and one that fails prematurely, leading to costly corrosion, peeling, and structural compromise.

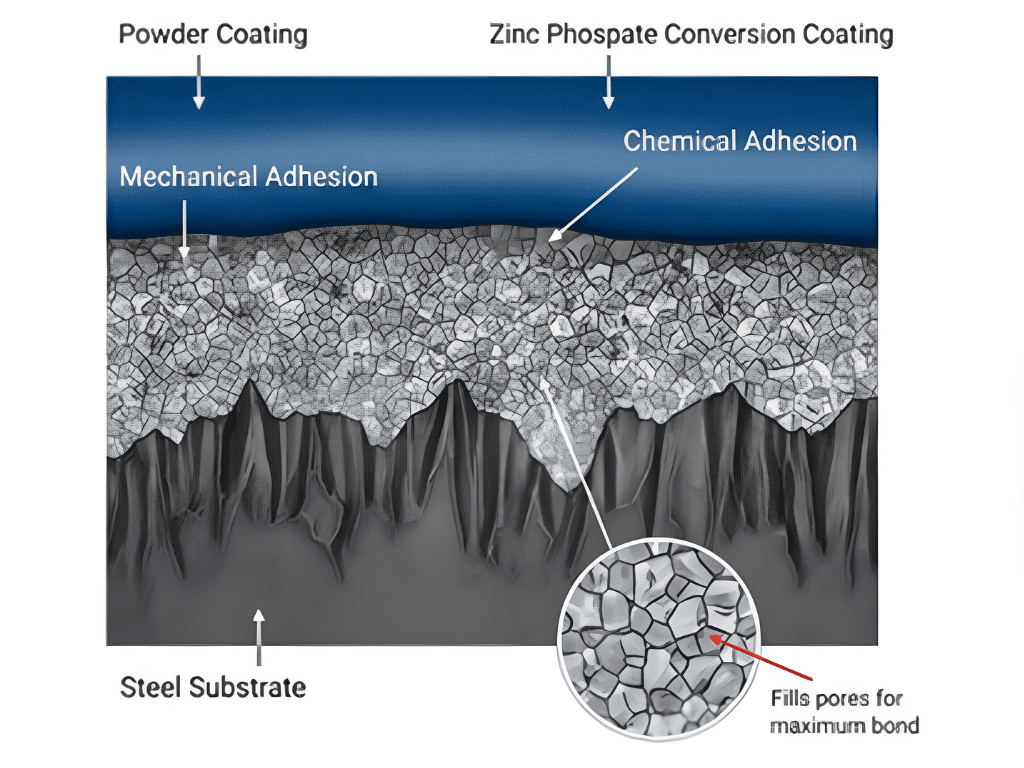

The modern standard for premium, long-lasting coating systems involves two non-negotiable phases: Abrasive Blasting (for mechanical keying) and a Zinc Phosphate Conversion Coating (for chemical bonding and rust inhibition). These processes are not optional extras; they are the critical foundation upon which true coating longevity is built.

The Foundation of Failure or Success: Understanding Adhesion

Why does a coating fail? Almost always, it comes down to a lack of adhesion. Adhesion occurs on two levels:

- Mechanical Adhesion (Physical Lock): The coating physically flows into microscopic peaks and valleys on the metal surface, creating an ‘anchor profile.’

- Chemical Adhesion (Molecular Bond): The coating forms a chemical bond with a clean, converted layer on the substrate, preventing the lateral spread of corrosion beneath the film.

When pre-treatment is inadequate, surface contaminants—such as mill scale, rust, oils, or weld flux—become the point of contact instead of the raw metal. The powder coating adheres to the contamination, which has no inherent bond to the steel, causing the entire system to fail quickly. This is where the two-pronged approach of blasting and chemical conversion becomes vital.

Phase 1: Abrasive Blasting—The Mechanical Imperative

For any steel component requiring maximum durability, particularly in industrial or exterior applications, simple washing is insufficient. Abrasive blasting (often referred to as sandblasting, though modern media varies) is the crucial first step that prepares the surface mechanically.

Why Blasting is Essential:

- Removal of Mill Scale: New steel components are often covered in mill scale, a flaky, bluish-black surface layer formed during the hot rolling process. Mill scale is brittle and non-uniform; if powder-coated, it will inevitably flake off, taking the coating with it. Blasting removes this completely.

- Rust and Contaminant Removal: Blasting strips away existing rust, old paint, heavy oxidation, and surface oils that chemical baths alone cannot fully eradicate. This ensures the chemical pre-treatment is working directly on clean, bare metal.

- Creation of the Anchor Profile: The main purpose of blasting is to create a specific surface profile—often described as an “anchor tooth.” This profile consists of peaks and valleys, typically measured in microns (µm). A properly blasted surface is rough, providing a high surface area for the powder to grip and mechanically lock into once cured. The target profile depth must be carefully controlled; too shallow and adhesion is weak; too deep and coating thickness becomes inconsistent.

For high-performance coatings, specifications often call for an AS 1627.4 Class 2.5 (Near White Metal Finish). Achieving this level requires expertise, the right abrasive media (e.g., garnet or steel grit), and precision equipment, all of which Superior Coaters provides, particularly for large-scale assets where consistency across a 14-meter span is challenging.

Phase 2: Zinc Phosphate Conversion Coating—The Chemical Shield

Once the metal surface is mechanically clean and profiled, it is ready for the chemical phase. This step separates a basic coating job from a professional, long-term durable solution. Simple wash and degrease systems only clean the surface; a conversion coating chemically transforms it.

Superior Coaters exclusively employs a robust Zinc Phosphate conversion coating process for high-performance projects, which is vastly superior to the more common and cheaper iron phosphate systems.

The Science of Zinc Phosphate:

- Chemical Reaction: The cleaned steel is immersed in a multi-stage process involving an acidic zinc phosphate solution. This acid reacts with the iron in the steel, converting the smooth metal surface into a dense, interlocking layer of insoluble zinc phosphate crystals.

- Crystalline Structure: These crystals are highly porous and structured like a microscopic, dense rock formation. This structure achieves two vital objectives:

- Maximised Mechanical Lock: The cured powder coating fills the microscopic pores and voids in the crystalline layer, enhancing the mechanical adhesion started by the abrasive blast.

- Superior Corrosion Resistance: Crucially, the zinc phosphate layer is chemically inert. It acts as an effective barrier against the spread of rust. Should the topcoat be scratched, the rust cannot easily spread laterally beneath the coating film, localizing the damage and significantly delaying failure.

Zinc Phosphate vs. Iron Phosphate:

Many commercial coaters use an Iron Phosphate system, which is faster and cheaper. While iron phosphate provides a clean surface, it forms an amorphous (structureless) layer that is thinner and less porous.

|

Feature |

Zinc Phosphate Conversion Coating |

Iron Phosphate Wash System |

|

Structure |

Dense, Crystalline (Forms an anchor) |

Amorphous (Structureless) |

|

Layer Thickness |

Thicker and more substantial |

Thinner, minimal build-up |

|

Corrosion Resistance |

Excellent. Highly resistant to under-film creep. |

Fair. Minimal barrier, corrosion spreads easily. |

|

Adhesion |

Superior (Mechanical + Chemical bond) |

Good (Mainly chemical bond) |

|

Use Case |

Industrial, Architectural, Coastal, Heavy-Duty |

Light-duty, interior, decorative |

For any structure facing aggressive environments—from the sun-drenched Queensland interior to the salt-laden air of Brisbane’s coastline—the minimal protection offered by iron phosphate is simply inadequate. Zinc Phosphate is the necessary investment for long-term protection.

The Australian Conditions Imperative

The stringent standards of pre-treatment are amplified by the unique challenges presented by the Australian climate:

- High UV Exposure: Intense solar radiation can degrade the binder in the coating, leading to chalking. A robust pre-treatment is necessary to maintain adhesion even as the topcoat ages.

- Coastal Salt Air: Salt spray and high humidity accelerate corrosion exponentially. The crystalline structure of zinc phosphate acts as the last line of defence against osmotic blistering and under-film corrosion creep caused by chlorides penetrating the coating film.

- Heavy Industry Demands: Components used in mining, energy, and heavy infrastructure face constant vibration, abrasion, and chemical exposure. Only the strongest coating systems, rooted in superior pre-treatment, can survive these stresses without premature failure.

Superior Coaters’ Guarantee: Quality Control and Expertise

At Superior Coaters, our commitment to quality extends far beyond the final colour application. We operate a state-of-the-art facility designed to handle both the mechanical and chemical demands of industrial-grade coating. Our process ensures:

- Precise Profile Measurement: Post-blasting, surface profiles are measured to ensure optimal anchor tooth depth is achieved across the entire component.

- Chemical Control: Our Zinc Phosphate chemical baths are rigorously monitored and maintained to ensure the concentration, temperature, and immersion times are perfect for forming a uniform, high-density crystal layer.

- Maximum Lifespan: By integrating professional abrasive blasting with the best-in-class Zinc Phosphate conversion coating, we eliminate the primary causes of powder coating failure, delivering a finish that meets and exceeds industry standards like AS 4506 (Metal finishing – Thermoset powder coatings).

For your next project—whether it’s a critical structural beam, architectural façade, or a fleet of industrial machinery—don’t compromise the integrity of your assets by accepting a second-rate pre-treatment process. The longevity of your investment hinges on the steps taken before the powder gun is even loaded.

To discuss your high-performance coating needs and understand how our rigorous two-phase pre-treatment system guarantees your project’s durability, contact the experts at Superior Coaters today.

07 3375 6777

07 3375 6777