If you’ve had metal powder-coated in a standard colour like black or white, you may think the process is simple. But silver and gold powder coatings are a different story.

These metallic finishes look stunning. But they are also complex. The shine, reflectivity, and colour depth make them difficult to apply. Every step of the process must be precise.

At Superior Coaters, we know how challenging metallic powder coating can be. From surface prep to curing, every detail matters.

Why Metallic Powder Coatings Are Different

Silver and gold powder coatings contain metallic flakes. These tiny flakes create the signature metallic effect.

But metallic flakes behave differently than normal powder. They are heavier and may not spread evenly. This can cause uneven colour or blotchy finishes.

Electrostatic application also becomes tricky. If the flakes don’t charge correctly, they won’t stick. This makes achieving a uniform silver or gold finish harder.

Surface Preparation is Critical

Any metallic powder coating job starts with perfect preparation.

Even a small speck of dust or oil can ruin the finish. Contaminated surfaces can lead to discoloration or poor adhesion.

Grounding is also crucial. Metallic powders need the right electrical charge to stick. Poor grounding causes patchy areas.

Parts with complex shapes can be even harder. Metal corners and cavities can prevent powder from reaching the surface evenly.

Electrostatic Application Challenges

Spraying metallic powder is not as simple as it sounds.

The spray gun’s voltage, airflow, and powder feed must be perfect. Too far from the surface, and flakes drop out early. Too close, and clumping occurs.

Even small changes in technique can ruin the metallic effect. Skilled operators are essential for silver and gold powder coating.

The Curing Process

Curing is another critical step.

Metallic powders need exact temperatures. Too hot or too cold, and the finish can bloom or haze. Large parts heat unevenly, causing inconsistent colour.

Curing must be consistent across batches. Otherwise, colours may not match between different components.

Colour Matching and Repeatability

Silver and gold finishes are hard to replicate.

Powder batch differences, spray technique, and curing variations can change the colour. Even slight changes are noticeable because metallic flakes reflect light.

This is why metallic powder coating requires careful quality control. Mistakes can mean wasted powder and failed parts.

When Metallic Powder Coating is Worth It

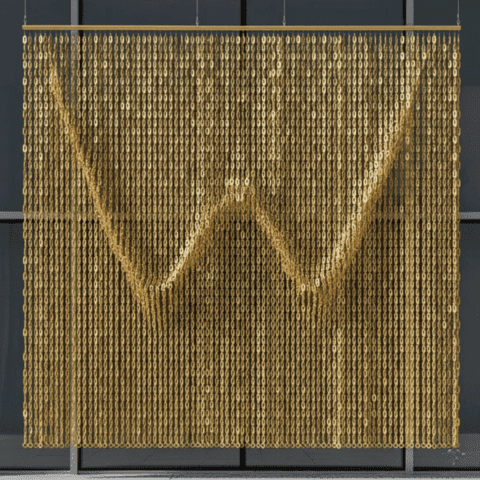

Silver and gold finishes are expensive and challenging. But the results are worth it.

They are ideal for decorative metalwork, architectural elements, and premium projects.

Good candidates include:

- Balustrades and handrails

- Gates and fencing

- Shade structure frames

- Small to medium-size parts with high visibility

Poor candidates include:

- Large, multi-part projects with multiple coating runs

- Components exposed to extreme wear or UV light

- Functional parts where colour is not critical

Why Experience Matters

At Superior Coaters, experience is key.

Applying metallic powder coating requires:

- Perfect surface preparation

- Skilled spray operators

- Consistent curing

- Strict quality control

Mistakes in any step can ruin the finish. But with care, silver and gold powder coatings are stunning and durable.

Conclusion

Silver and gold powder coatings look amazing. But they are not simple. Every stage, from prep to curing, requires precision.

For projects that need a premium finish, metallic powder coatings are worth the effort.

At Superior Coaters, we handle these challenges daily. We deliver beautiful, durable, and flawless metallic finishes for any project.

07 3375 6777

07 3375 6777