In industries where metal components must stand up to the harshest elements, durability and performance are non-negotiable. From mining equipment and agricultural machinery to large-scale infrastructure, powder coating has become the finish of choice across countless sectors. But what makes powder coating so effective, and why is it so widely adopted in industrial applications?

Let’s take a closer look at the science behind powder coating, its advantages, and how companies like

Superior Coaters are leading the way in delivering high-quality, long-lasting finishes for clients across Australia.

What Is Powder Coating?

Powder coating is a dry finishing process that involves applying a fine, electrostatically charged powder to a metal surface. The powder, typically made from thermoplastic or thermoset polymers, is cured under heat to form a smooth, hard coating that’s more resistant to wear, corrosion, and fading than traditional liquid paint.

Unlike liquid paints, powder coating contains no solvents. This makes it more environmentally friendly, safer to handle, and less prone to application issues like sagging or running.

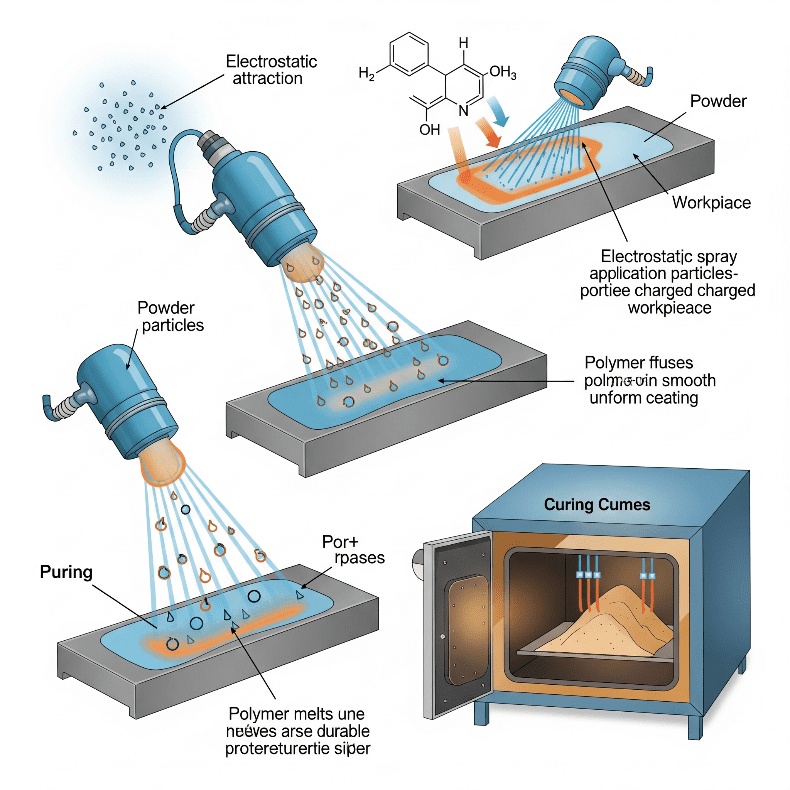

The process consists of three main stages:

- Surface Preparation: The metal is cleaned and pre-treated to ensure optimal adhesion. This may involve abrasive blasting, chemical treatment, or phosphate washing.

- Powder Application: Using a spray gun, powder is electrostatically charged and sprayed onto the grounded metal part. The charge causes the powder to cling evenly to the surface.

- Curing: The coated part is placed in an oven and heated to 180–200°C, melting the powder into a smooth, durable finish.

The Science Behind Its Strength

The strength of powder coating lies in its cross-linked polymer structure. During curing, thermoset powders undergo a chemical reaction that permanently changes their molecular structure. This cross-linking enhances chemical and thermal resistance, making the coating extremely tough.

Unlike paint that dries via evaporation, powder coating melts and flows into a uniform layer before it hardens. This results in a thicker, more consistent film with fewer imperfections.

Powder coatings also adhere mechanically and chemically to the metal surface, especially when pre-treatment is done correctly. The bond is not only strong but also flexible, allowing the coating to withstand impact and thermal expansion without cracking or peeling.

Why Industries Rely on Powder Coating

-

Exceptional Durability

In heavy-duty applications such as mining, construction, and agriculture, surfaces are exposed to abrasive materials, UV radiation, chemicals, and extreme weather. Powder coating stands up to these challenges better than conventional paint.

It resists corrosion, chips, scratches, and fading—crucial in environments where maintenance downtime is costly.

-

Environmentally Friendly

Powder coating contains no harmful volatile organic compounds (VOCs), making it a much cleaner process than solvent-based paints. Overspray can also be collected and reused, reducing waste.

With increasingly strict environmental regulations, industries are opting for sustainable finishing solutions that meet compliance without sacrificing performance.

-

Cost-Effective Over the Long Term

While the upfront cost of powder coating may be slightly higher than wet paint, the longevity of the coating means fewer repaints and lower maintenance costs over time. This makes it a smart investment for long-term operational efficiency.

-

Superior Finish and Aesthetics

Powder coatings provide a smoother, more even surface with a variety of finishes available—including matte, gloss, metallic, textured, and custom colours. This allows businesses to meet both functional and branding requirements with ease.

Powder Coating in Action: Industrial Applications

At Superior Coaters, powder coating is more than just a finishing touch—it’s a science-driven service tailored for performance in real-world applications.

Some of the most common industrial uses include:

- Street Light Poles and Infrastructure: Long-lasting finishes that resist corrosion from weather and pollution.

- Mining Equipment: Protection against wear from abrasive environments and exposure to chemicals.

- Agricultural Machinery: Robust coatings that withstand mud, UV exposure, and extreme temperatures.

- Transport and Logistics Components: Long-haul trucks, trailers, and transport infrastructure benefit from strong and visually consistent finishes.

With the ability to handle oversized items up to 14 metres long, Superior Coaters offers capabilities few others in Queensland can match. Their state-of-the-art powder coating facilities are designed to handle both large-scale commercial jobs and high-volume production runs efficiently and with precision.

Quality Control and Testing

Industrial-grade powder coating isn’t just about applying a finish—it’s about delivering reliable, tested performance. Quality control involves:

- Adhesion Testing: Ensures the coating bonds properly to the substrate.

- Salt Spray Testing: Simulates corrosive environments to assess long-term durability.

- Impact and Flexibility Tests: Verify that the coating can withstand mechanical stress without cracking or peeling.

Reputable providers like Superior Coaters invest in rigorous quality control processes, giving clients peace of mind that their equipment or infrastructure will hold up over time.

Choosing the Right Powder Coating Partner

Industrial applications demand more than just a quick spray and bake. You need a partner who understands the unique requirements of your industry and can deliver consistent, high-quality results at scale.

When choosing a powder coating provider, look for:

- Proven experience with industrial projects

- The ability to handle oversized or high-volume components

- In-house surface preparation and pre-treatment facilities

- Compliance with Australian standards and environmental best practices

- Transparent turnaround times and customer support

Superior Coaters ticks all these boxes, earning the trust of clients across Brisbane and regional Queensland. Whether it’s for a large infrastructure job or custom fabricated parts, their team brings technical expertise and a commitment to excellence in every project.

Final Thoughts

Powder coating is more than just a protective finish—it’s a science-based solution that enhances performance, reduces maintenance, and contributes to a cleaner environment. Its chemical strength, thermal resilience, and outstanding visual finish make it the go-to choice for demanding industrial applications.

For businesses looking to extend the life of their metal components while maintaining superior aesthetics, powder coating is an investment in quality, durability, and sustainability.

Ready to see what expert

powder coating can do for your business? Contact Superior Coaters today to discuss your next industrial project.

07 3375 6777

07 3375 6777