Hot-Dip Galvanising (HDG) is one of the world’s most effective and time-tested methods for protecting steel. By submerging fabricated steel in molten zinc, a metallurgically bonded coating is formed, offering exceptional, long-term corrosion resistance for decades.

This superior protection makes HDG the material of choice for infrastructure, structural steel, marine environments, and any project where durability is non-negotiable.

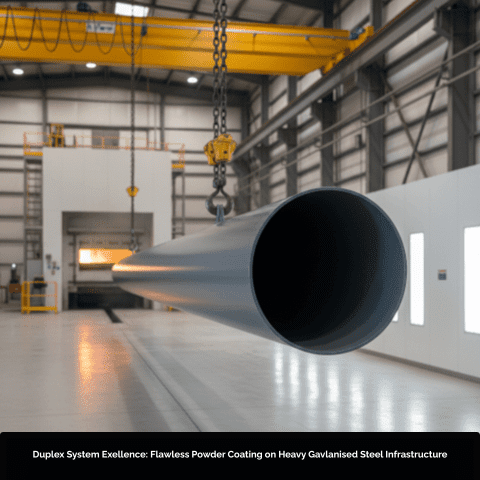

However, once that essential layer of zinc is applied, a new challenge emerges: applying a secondary, aesthetic, and even more protective coating over the top. While HDG steel is the foundation of durability, successfully powder coating hot-dip galvanised steel is a process fraught with unique complexities. Without the correct, meticulous procedure, a powder coated finish can quickly develop surface imperfections, pinholes, or worst of all, premature flaking—entirely defeating the purpose of the premium coating.

At Superior Coaters, we don’t just apply powder; we master the adhesion. With over 35 years of experience and state-of-the-art facilities, we have perfected the “Superior Technique”—a comprehensive, multi-stage process specifically engineered to ensure a flawless, long-lasting bond between the powder and the galvanised substrate.

This article delves into the critical differences required for this specialist coating process, explaining the HDG dilemma, the indispensable pre-treatment steps, and why choosing an accredited specialist is the only way to guarantee the integrity of your finish.

Section 1: The HDG Dilemma—Why Powder Coating Galvanised Steel is Tricky

Hot-dip galvanising works by forming a series of zinc-iron alloy layers topped with a layer of pure zinc. This zinc surface, while chemically protective, presents two primary challenges for powder coating applicators:

- The Outgassing Problem

This is the most common and visible failure when powder coating galvanised steel. When HDG steel is heated—a necessary step for curing the powder coating—gases and moisture trapped within the porous zinc layer are released. As these gases escape through the molten powder coating film, they create tiny craters, pinholes, or bubbles on the finished surface. This is known as “outgassing.”

These imperfections not only ruin the aesthetic appeal but also compromise the powder coating’s barrier function, creating pathways for moisture and corrosive elements to penetrate the zinc layer, leading to premature failure of the entire system.

- The Adhesion Problem

Zinc is a reactive, smooth, non-ferrous metal. Unlike bare steel, which can be easily profiled for adhesion, the galvanised surface is smooth, often oxidised, and difficult for a standard powder coat to bond with. Using the wrong preparation or skipping chemical conversion steps will result in poor mechanical and chemical adhesion, causing the powder coating to peel, flake, or delaminate from the surface within a short period.

In short, for the dual-layer protection system to work (the Duplex System), you need an applicator who understands that the prep work for HDG steel powder coating is completely different—and far more rigorous—than for standard steel.

Section 2: The Critical First Step: The Superior Pre-Treatment Process

The core of our Superior Technique lies in an uncompromising, four-stage pre-treatment system designed to neutralise the problems of outgassing and poor adhesion. We focus on preparing the surface chemically and physically before the powder is even introduced.

Stage A: Meticulous Cleaning and Degreasing

The process begins with the complete removal of contaminants. HDG steel often carries traces of oils, dirt, or residues from the galvanising process. Our cleaning phase uses specialised, industrial-grade detergents and hot chemical washes to ensure the surface is chemically clean and free of all organic and inorganic compounds. Any remaining residue will interfere with subsequent steps and prevent proper adhesion.

Stage B: The Essential Etching (Chemical Conversion)

This is a non-negotiable step for powder coating galvanised steel. Instead of simply washing the zinc, we subject the surface to a controlled etching process. This chemical conversion coating achieves two things:

- Removes Surface Oxides: It removes the passive zinc oxide film that naturally forms on the surface, which is a key inhibitor of adhesion.

- Creates a Bond Profile: It generates a micro-crystalline or amorphous phosphate layer (chromate-free for safety and environmental compliance) that is intrinsically receptive to the powder coating. This layer is the crucial chemical ‘key’ that locks the powder to the zinc.

Stage C: The Critical De-gassing (Bake-Out) Phase

This stage is the most vital step in preventing the catastrophic outgassing that leads to pinholes. After pre-treatment, the galvanised steel is subjected to an initial, controlled heating cycle—the ‘bake-out’—at a temperature slightly above the final powder curing temperature.

This pre-bake forces the trapped gases and moisture to escape the zinc layer before the powder coating is applied. This is where the advantage of Superior Coaters’ large-scale facilities becomes apparent. Our expansive ovens—among the largest in Australia—allow us to accommodate even the largest components (up to 14 metres long) and subject them to the necessary uniform, high-temperature bake-out, ensuring comprehensive de-gassing across the entire surface.

Only once the metal has completed its pre-bake and cooled to a manageable temperature is it ready for the application booth.

Section 3: Selecting and Applying the Right Powder

Pre-treatment accounts for 80% of the success, but the remaining 20% rests on material selection and application quality. The choice of powder and the expertise of the applicator are paramount.

The Importance of Powder Type and Choosing the Right Specification

A standard powder may not be suitable for a galvanised surface, even with perfect pre-treatment. Superior Coaters utilises premium powder products from accredited suppliers like Dulux and Interpon, specifically formulated for difficult substrates. In many cases, we recommend a Duplex System approach involving a specialised zinc-rich primer:

- Primer Layer: A high-build, zinc-rich epoxy primer is applied first. This primer is designed to have superior flexibility and wetting properties to maximise adhesion to the prepared zinc substrate. It acts as an additional sacrificial layer.

- Top Coat: A robust, UV-stable polyester or polyurethane topcoat is then applied over the cured primer. This provides the aesthetic finish, colour, and protection against the elements.

This two-layer system provides an unparalleled level of corrosion protection and adhesion integrity, vastly exceeding the performance of a single-coat application.

Precision Application and Quality Control

Our designation as a Dulux-accredited powder coating facility is a testament to our quality and precision. Our technicians use calibrated, state-of-the-art electrostatic application equipment to ensure a uniform film thickness—a critical factor for aesthetic consistency and performance.

Furthermore, we operate under a rigorous Quality Assurance System. Every project, especially specialised jobs like powder coat hot-dip galvanized steel, undergoes documented process testing, final thickness inspection, and certified results. This commitment to quality ensures that the finished product meets or exceeds industry standards for adhesion and durability.

Section 4: The Superior Coaters Difference—Expertise That Guarantees a Lasting Bond

The process of coating HDG steel is a high-stakes undertaking. When you factor in the cost of galvanising, fabrication, and large-scale project logistics, failure in the coating stage is simply not an option.

This is why engaging a Brisbane powder coating specialist with a proven track record in heavy industrial and architectural projects is essential.

- Experience: With over 35 years in the industry, Superior Coaters has encountered—and successfully solved—every challenge associated with galvanised steel coating. We don’t rely on generic methods; we use proprietary, refined techniques developed over decades.

- Capacity: Our ability to de-gas, coat, and cure items up to 14 metres long means we can handle entire street poles, complex bridge components, and industrial infrastructure that smaller, less-equipped facilities cannot. Our capacity is matched by our capability.

- Guaranteed Adhesion: Our confidence in our four-stage pre-treatment and bake-out process allows us to guarantee the adhesion and durability of the finish. We deliver a Duplex System that not only looks impeccable but is engineered to protect your assets for the maximum possible lifespan.

Don’t risk your project’s integrity with a compromised finish. For steel assets designed to last a lifetime, you need a coating that can keep up.

To discuss your next project requiring specialist powder coating galvanised steel, and to put the Superior Technique to work for you, contact our team of experts today.

07 3375 6777

07 3375 6777