Powder coating has come a long way from being a simple protective finish. Today, it’s a highly engineered system combining durability, sustainability, and aesthetic versatility — qualities that have made it the preferred solution for everything from architectural façades to heavy-duty industrial assets. As new technologies and materials continue to evolve, powder coating is entering an exciting new era of performance and design freedom.

For businesses, fabricators, builders, and architects in Australia, understanding these innovations isn’t just interesting — it’s commercially valuable. Whether you’re powder coating fences, large-scale structures, industrial parts, or custom architectural elements, the next generation of powder coating technology can improve longevity, reduce maintenance, and deliver more consistent results across all applications.

Below, we explore the biggest innovations shaping the future of the industry — and how each one can impact your next project.

1. Smarter, Stronger and More Durable Powder Coatings

Advances in resin technology and curing systems are delivering coatings that outperform traditional applications across durability, chemical resistance, UV stability, and hardness.

One of the biggest leaps is in industrial durability, where new formulations are extending the life of assets exposed to harsh environments such as coastal regions, heavy industry, and transport infrastructure. You can learn more about how long-lasting coatings are being achieved in Superior Coaters’ deep dive into

industrial durability.

For architectural projects, enhanced two-coat systems remain a strong performer. A great example is the

two-coat chrome powder finish, which delivers outstanding gloss retention and corrosion resistance while still offering a premium metallic look.

These technological improvements allow fabricators and builders to specify finishes with greater confidence that they will remain stable and visually appealing for many years — even in Australia’s extreme climate.

2. Preparing Surfaces with Precision for Longer-Lasting Results

Another major innovation area is improved pre-treatment, which significantly boosts coating adhesion and corrosion resistance. The evolution of pre-treatment processes — such as

zinc phosphate blasting — is critical for ensuring longevity in coastal or industrial applications.

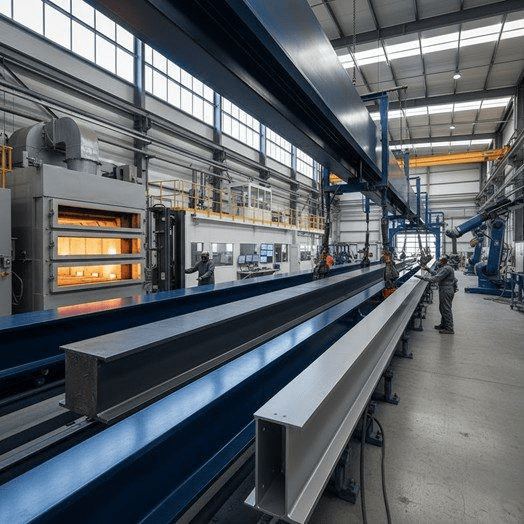

Proper pre-treatment has become even more important as structures grow in size and complexity. For oversized materials, Superior Coaters uses advanced handling systems and Australia’s largest ovens — including

14-metre ovens designed for oversize powder coating — which allows large sections to be pre-treated and coated in one seamless, consistent workflow.

These advancements are essential for commercial builders requiring coatings that resist rust, UV and everyday use — from

fence powder coating services to structural steel, shade structure components, and metal fabrication.

3. Coating Massive and Oversized Structures Without Compromise

Large structures require a specialised approach, especially when consistent curing and uniform coverage are essential. Cutting-edge technology now allows even the biggest architectural and industrial elements to be coated with precision.

Superior Coaters specialises in

oversized powder coating solutions, including extremely large, heavy, and complex pieces — and even provides a second dedicated process for

oversized structures requiring advanced specifications.

This innovative capability supports industries working with large spans, long beams, and architectural structures such as:

- Mining equipment

- Balustrades and façades

- Shade and tensile structures

- Transport infrastructure components

The company’s experience in

working at scale for massive shade structures shows how far oversize coating technology has come — and how important it is for projects requiring both durability and visual consistency.

4. Colour and Finish Innovations for Architecture and Design

Beyond performance, powder coating is shifting rapidly in the world of design. Architects are no longer limited to a narrow range of colours and gloss levels — trends now include textured, matte, mineral, metallic and specialty finishes.

The growing popularity of bespoke architectural finishes can be seen in the rise of

custom colour trends, allowing designers to achieve visually striking outcomes without sacrificing durability.

Advanced finishes include:

- Textured matte blacks

- Warm metallics such as copper or bronze

- Woodgrain and stone-like finishes

- Ultra-durable coastal architectural colours

For clients weighing raw metal versus coated metal options, Superior Coaters provides insights through its comparison of

copper-bronze powder coating vs raw metal.

5. Smarter Coating Specification for Reliability and Compliance

With so many coating types available, choosing the right system is becoming both more complex and more important. Businesses benefit significantly from understanding how to specify the correct system for their environment, exposure and use case.

Superior Coaters provides extensive guidance on

choosing the right powder coating specification and

matching industrial needs with coating performance — critical for developers, engineers and asset managers.

The innovations in specification go hand-in-hand with innovations in protective coating systems, including complete lifecycle-focused solutions discussed in

choosing the right industrial coating system for long-term protection.

6. Sustainability and Energy-Efficient Coating Technologies

Sustainability is no longer optional in construction and manufacturing. Powder coating is inherently greener than wet paint — it contains no solvents, produces minimal waste, and supports full reclaiming of overspray.

But the newest innovations go even further, focusing on:

- Lower-temperature curing technology

- Efficient ovens

- Recyclable materials

- Longer life cycles reducing material replacement

This aligns with modern environmental compliance requirements in Australia and supports high-durability systems such as

metal powder coating services that extend asset lifespan.

7. Smarter Quality Assurance and Accredited Warranties

Quality systems are becoming more rigorous thanks to digital tracking, advanced testing methods and third-party certifications. Superior Coaters’ status as a

Dulux Accredited Powder Coater provides stronger warranties and proof that the work meets strict Australian standards.

This gives builders and architects peace of mind, especially in demanding environments such as coastal regions, where high-performance solutions — like those covered in

coastal powder coating protection — are essential.

8. Avoiding Common Mistakes and Improving Results

As coatings become more advanced, ensuring correct application becomes even more important. Superior Coaters highlights both how to achieve the

perfect powder coating results and

which common coating mistakes to avoid.

Combined with modern innovations, this knowledge empowers clients to achieve superior outcomes on every project.

Explore What’s Next in Powder Coating

The powder coating industry is advancing rapidly — and businesses that stay ahead of these innovations will benefit most. Superior Coaters’ dedicated resource on

emerging powder coating innovations and trends provides deeper insights into what’s coming next.

From new materials to smarter processes, enhanced colours to sustainable technology, the future of powder coating promises even higher levels of performance, aesthetic freedom and reliability.

07 3375 6777

07 3375 6777